On a bitterly cold Sunday morning last winter I started scratching out ideas of different arrows I could build for my upcoming African buffalo hunt. The following day I started ordering different components and I organized them into different groups as they arrived in the mail.

Over the next 6 months I was forced to go back to the drawing board six times to finally come to a combination of components that would tune to the desired up-front components.

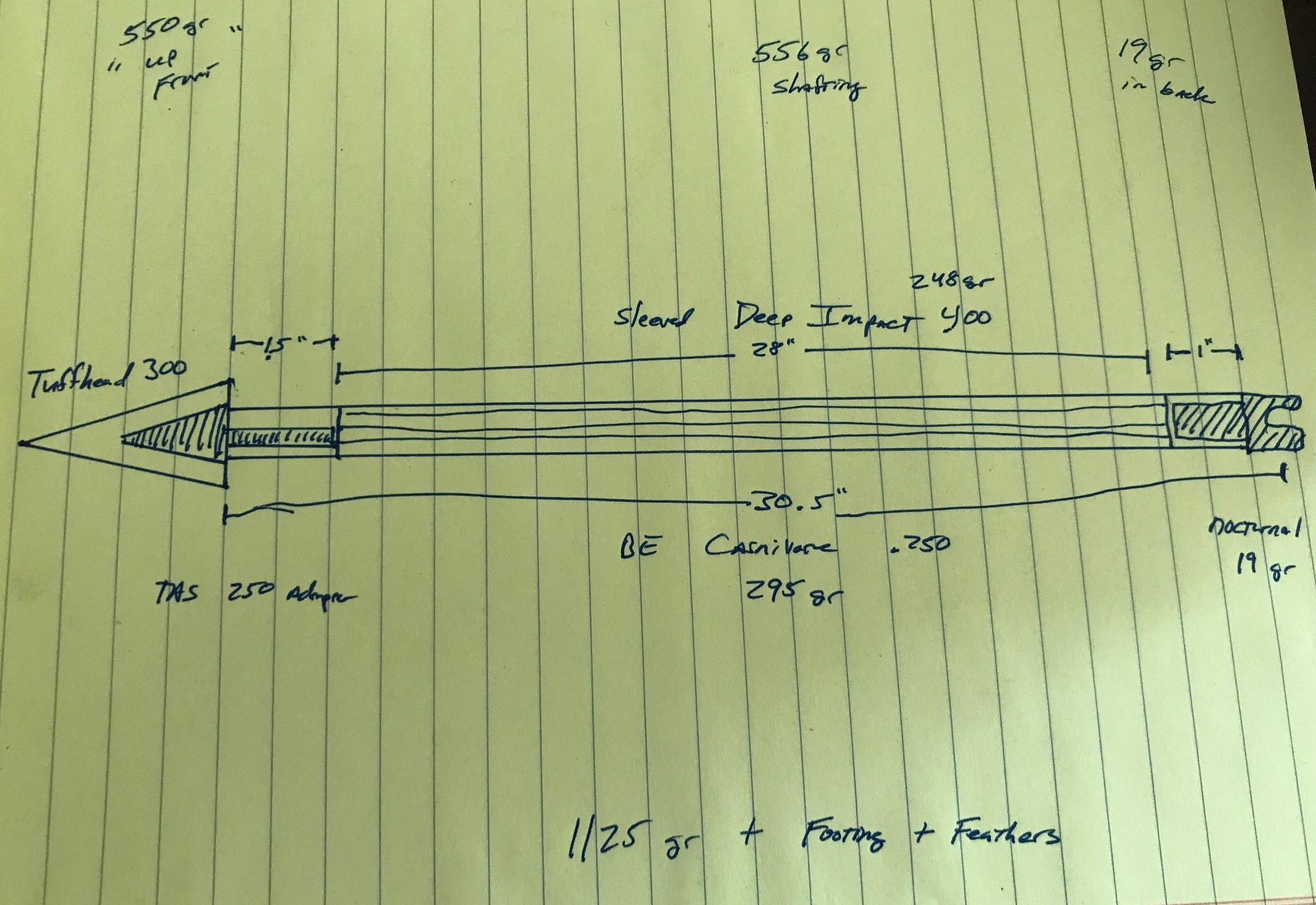

After having every .250 spine shaft be too weak, I ended up with the most complicated arrow of all my January scratch pad ideas. It has extra parts to fail and I had hoped to avoid it. I was not willing to change out the 300 grain Tuffhead broadhead, or my 250 grain insert/adapters from Traditional Archery Solutions. Since every .250 shaft was too weak with 550 grains up front out of my 87# longbow, I had to sleeve another arrow shaft inside of it.

Simply Traditional sent me some Black Eagle Deep Impact .400 spine shafts that I epoxied inside of my Black Eagle Carnivore .250 shafts. My initial test I used 8″, 16″, and 24″. The 8″ sleeved arrow was still too weak, the 24″ sleeved arrow was too stiff, but the 16″ sleeve came out just right.

The last thing I wanted to add was 2″ of aluminum footing, when I shoot I like to feel the footing touch my index finger as a draw check. I added the sections of 2216 to my first 3 test shafts with field points and started shooting them as bare shafts as well as through paper. I changed out the factory nocks for the illuminated nocks I covered in the past.

Testing with 2″ feathers would occasionally show a tear at close range through paper tuning, so I ended up going to four 3″ parabolic feathers at 90 degrees with a straight clamp. With arrow tuning complete I started testing integrity. After some hard hits I found the early arrows constructed with JB Weld and with 5 minute epoxy could have components loosen. Granted I was shooting concrete, rocks, and steel with them, I was hoping to drastically improve the overall integrity of my arrows now that the components and tune had been perfected. Enter golfers.

When I was done I had 15 arrows in my arrow box averaging over 1060 grains with an FOC well over 30%. After weighing, spin testing, and 10 test shots a piece, I took them to a paper wheel and some jewelers rouge yesterday. With that these arrows are in my luggage and ready to go looking for buffalo, hopefully we can find one!